The Connecticut Trading company was formed in 1907 and obtained an exclusive license to import and sell the German Practicus incandescent mantle burners in North America. The company immediately saw the advantage of being able to offer complete kerosene mantle lamps as well burners for lamp upgrades and turned to Plume & Atwood in nearby Waterbury Connecticut to manufacture lamp bases to go with their burner. Thus the American version of the Practicus lamp was born. Meanwhile Victor S. Johnson had founded the Western Lighting Company to sell mantle lamps using the imported Felbollin mantle burner. When he saw the new CONTACO lamps with the Practicus burner on Plume & Atweed fonts he sold his Felbollin franchise to the Minnesota Trading Company and received a franchise from

the Connecticut Trading Company to sell Practicus lamps with P&A fonts. Within a year Victor Johnson moved to Chicago Illinois to form the Mantle Lamp Company of America. In 1908 he filed the incorporation papers and applied for the trademark name "Aladdin". He immediately began recruiting sales agents to sell lamps. Early 20th century America and Canada were largely rural. Country wide sales were made by independent sales agents who were granted exclusive sales territories and went house to house to sell their products.

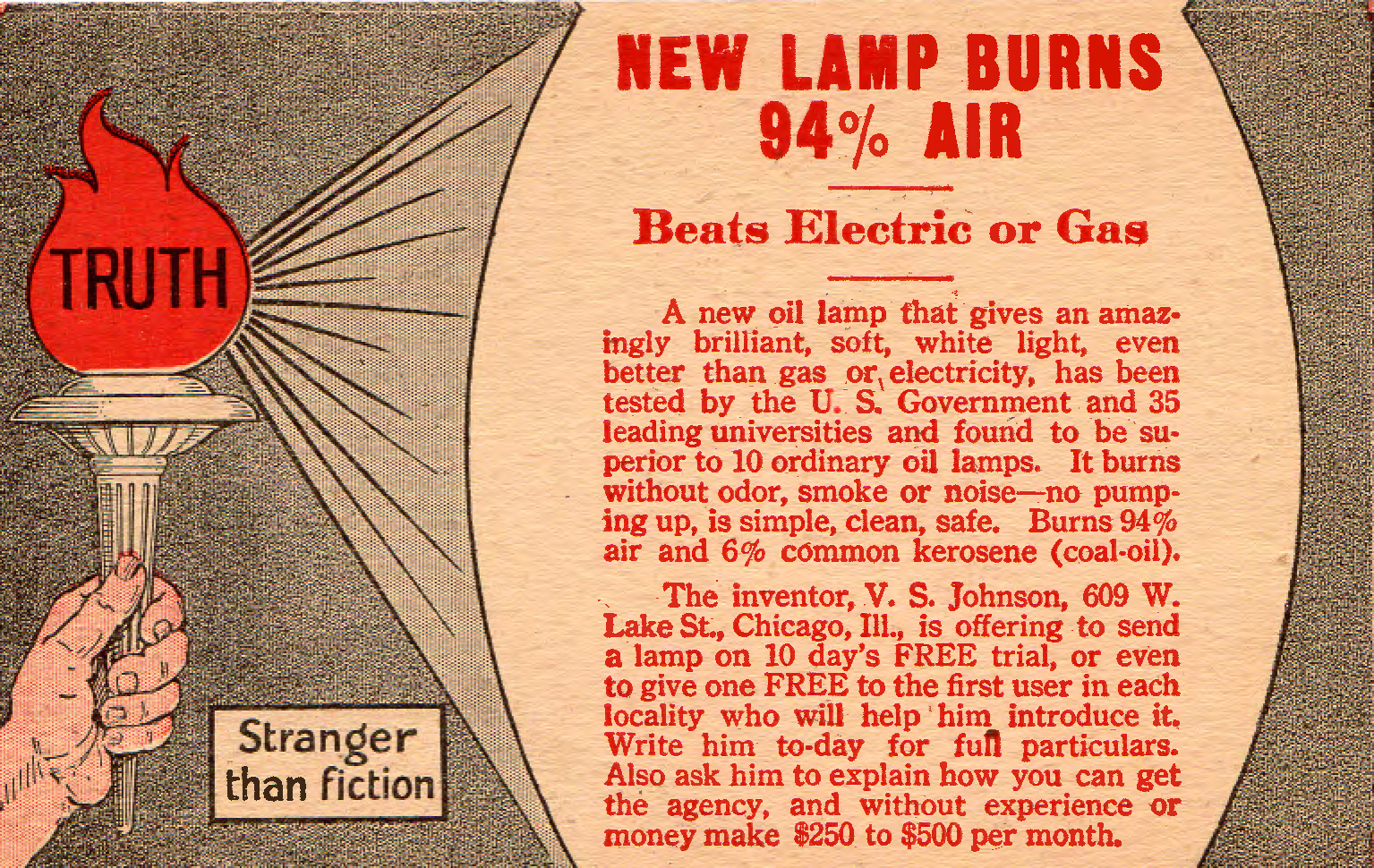

Click card to see pdf version

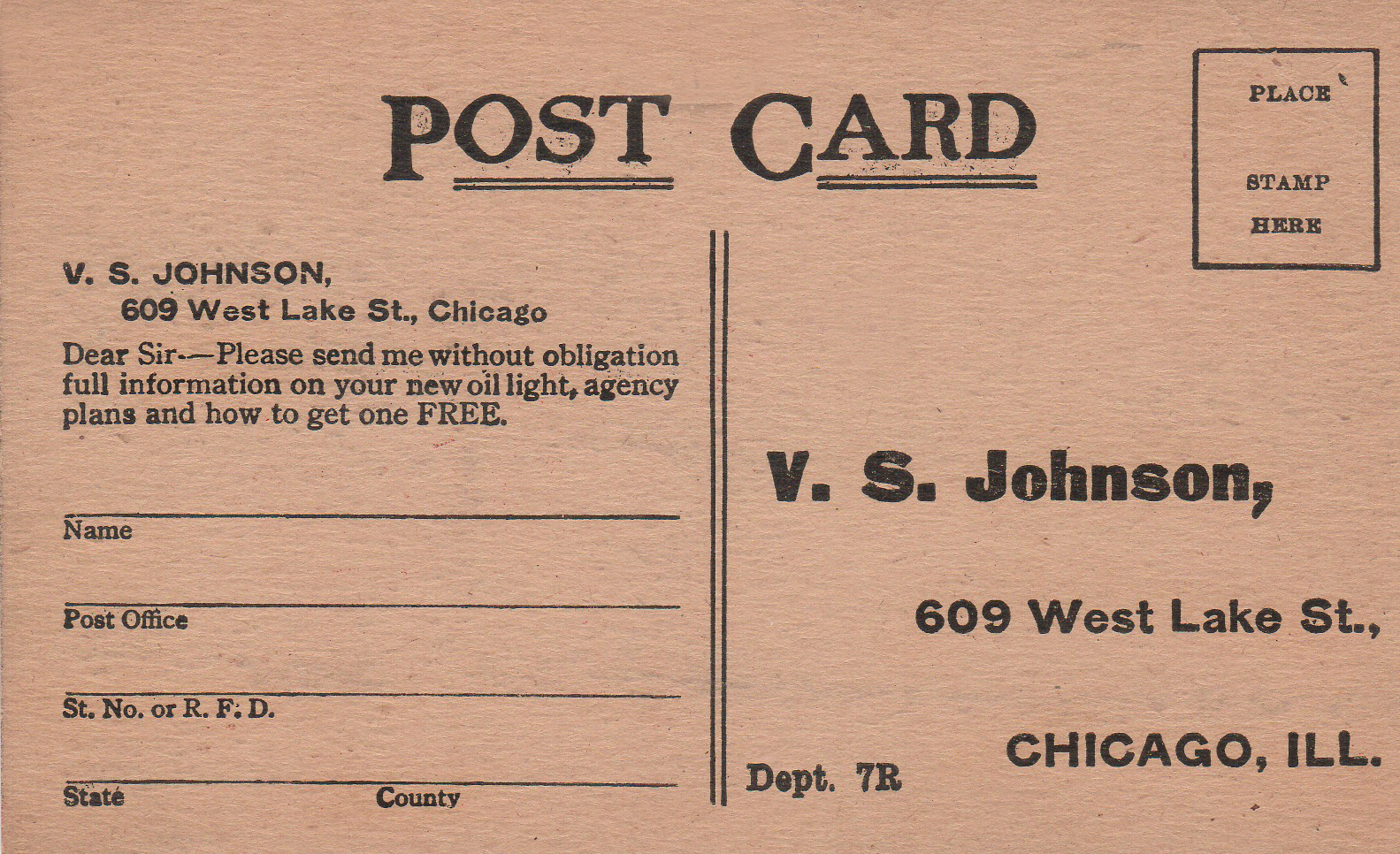

The early 1908 cards were used to recruit sales agents. Note that there is no company name mentioned. The card appears to have been made soon after Victor Johnson arrived in Chicago and before he was granted incorporation papers for the Mantle Lamp Company of America.

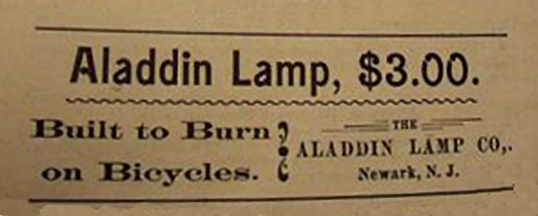

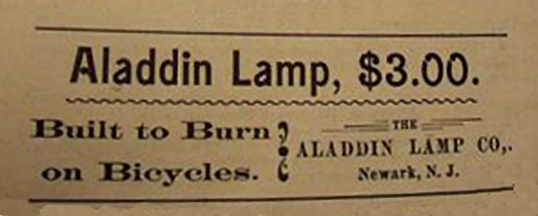

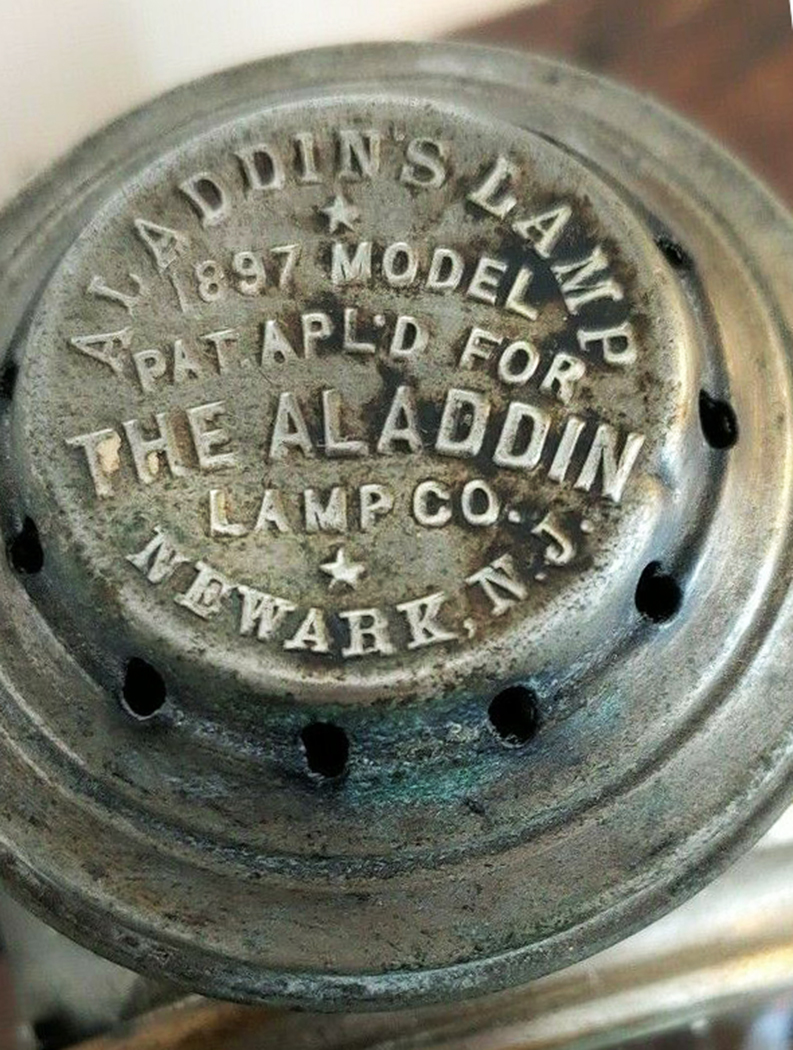

The company did not start out as Aladdin because there was an Aladdin Lamp Company already in existence at the time

1896 ad for Aladdin bicycle lamps

Since the Aladdin Light Company already had a trademarked company name, the Mantle Lamp company could not use that company name until the first company closed and the trademark ran out.

The original Aladdin Lamp Company manufactured and sold kerosene bicycle lamps.

In the meantime, Plume and Atwood, having gained experience with the Practicus burner designed and patented a centre draft and a side draft incandescent mantle burner. It appears that the Connecticut Trading Company started offering the center draft lamp developed by Plume & Atwood in April or May of 1908 under the CONTRACO trade name. In the same time frame Plume & Atwood sold their center draft lamps to other companies as well, creating such brands as Kim and Sunlight (not to be confused with the Sunlight brand mantle lamp later manufactured by the E. Miller & Co mantle lamp department for Montgomery Ward).

Something happened around late 1908 or early 1909. The Mantle Lamp Company which had been selling Practicus lamps under license from the Connecticut Trading Company suddenly stopped offering Plume & Atwood lamps with the Practicus burner and for a brief period offered lamps with the newly developed Sunbeam side draft burner on Plume & Atwood fonts.* This was soon followed by the Mantle Lamp Company ending up with a license to sell the centre draft lamps manufactured by Plume & Atwood under the brand Name of Aladdin. By Summer of 1909 The Mantle Lamp Company of America was offering the Aladdin model 1 lamp. The Mantle Lamp Company ceased selling Sunbeam lamps but continued offering the Sunbeam burner, followed by the Lumineer burner in 1913 as an incandescent mantle burner upgrade for owners of flat wick lamps.

The Mantle Lamp Company was able to start off the model 1

with three table lamp versions, two hanging lamp versions,

a wall mounted lamp and an oil pot lamp because the tooling

was already there. The lamp body tooling had already been developed for P&A's Royal family of round wick lamps and modified for use with the Practicus and the CONTRACO lamps.

The Aladdin model 1 and 2 lamps were generic P&A designed

centre draft mantle lamps. Early shades were generic off

the shelf glass shades for that era and the wall mount brackets, fount lamp hangers and shade holders

were all standard P&A products. The mantles and chimneys were imported from Germany. Within a couple years Aladdin

was contracting independent glass companies to produce glass

shades and chimneys. In 1911 Aladdin patented a new burner design that used a new "KoneKap" mantle. The company established their own in-house mantle manufacturing facilities to make their new patented mantle. The new burner and mantle became the model 3. The success of the Mantle Lamp Company was based primarily

upon their 1911 burner patent, Aladdin's innovative marketing, and the use of American made parts at the time WWI started.

The KoneKap Mantle

The models 1 and 2 lamps used a cap mantle that sat on a

cone shaped opening on the gallery. The mantle's spatial

relationship to the wick depended upon how the user assembled

the mantle on the gallery. If a cap mantle that

was not seated perfectly the lamp became finicky and tended to

burst into a carbon depositing flame before the whole mantle

was glowing.

The Mantle Lamp Company received it's first patent on 4 April

1911for an entirely new burner design that covered a new mantle, gallery, generator design and a new geared wick holder design. The new

mantle effectively moved the cone from the gallery to the

mantle and created a controlled more exact spacing by virtue

of the mantle locking into the new gallery. Their patent provided Aladdin with complete

control over manufacturing and sales of the KoneKap mantle.

And the KoneKap mantle's precision location on the gallery

created a much easier to operate and less fussy lamp than any

competitor had.

The new mantle, gallery and flame spreader were rushed into production as quickly as possible and

got phased into late model 2 lamp production (model 2-3 transition

lamp).

Marketing

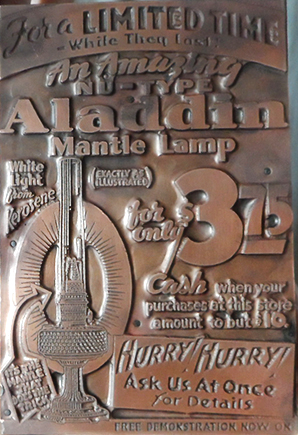

Victor Johnson realized the importance of marketing to support the company's rapidly growing force of retailers and independent sales agents. The company advertised in periodicals, over the radio and even with slides shown in movie theaters just before a movie began. They were always trying new promotions and

ways to sell product. Aladdin devised and offered marketing displays to allow retailers to showcase Aladdin brand lamps.

The company tried to have new

product to offer customers each year to generate renewed product interest and persuade

existing customers to upgrade, much in the same way as the

automotive industry. When they did not have functional improvements,

Aladdin incremented the model name by one and slid in appearance

changes when economical. For instance the model 10 and 11

lamps are marketing upgrades of the second year model 9 lamp.

Later the glass lamps allowed Aladdin to continually keep a new

mix of products in front of the customer to provide a constant

level of excitement. All this without having to increment

the burner tooling.

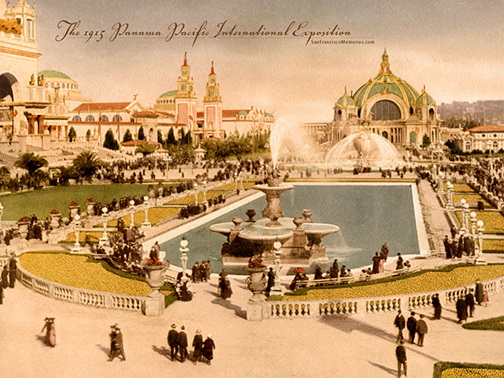

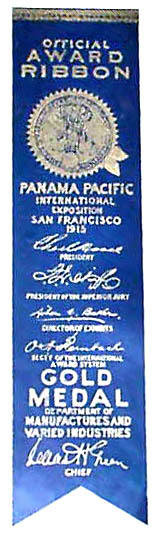

In 1915 Aladdin won a gold metal at the Panama Pacific International Exhibition in San Francisco for having the best kerosene lamp in the world with their model 6 Aladdin lamp.

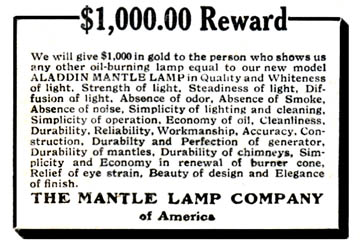

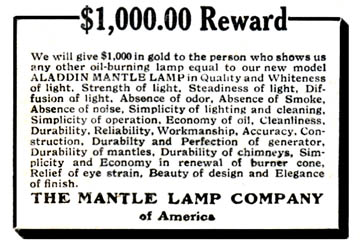

The Mantle Lamp company lost no time in advertising that they had the kerosene lamp judged to be the best in the world. They focused on the world fair award in their advertising and started offering a $1,000 reward to anyone who could prove that another lamp was better.

They stamped 1915 - 1916 onto the wick adjuster knob to make sure buyers would recognize the model 6 as the lamp that won at the world's fair. This is the only model of Aladdin lamp that was ever year stamped on the burner.

World War I

The mantle lamp industry was created in Germany where the

incandescent mantle was invented. Designing a mantle lamp

burner requires a fair amount of engineering and the technology

was developed by a few companies in Germany who saw financial

opportunities in expanding their market abroad. A large number

of partnerships between German burner manufacturers and American marketing entrepreneurs were formed in America where the marketing

company would purchase imported burners, place them on American

made lamp fonts and sell the resulting mantle lamps.

Aladdin

started out as such a company. Luckily they had switched to burners manufactured Plume & Atwood who had the engineering capability

to design their own incandescent lamp burners. 1914 started a British blockade of German merchant ships which halted the import of German made Lamp parts. This

quickly left lamp companies dependent solely upon German made burners without products to sell.

There was a limited return of German manufactured

mantle lamps between World War I and World War II such as

the lamps manufactured by Ehrich and Graetz sold by Montgomery

Ward during the 1930's. These of course disappeared when Europe entered into World War II in 1939.

After WWI Expansion

Victor Johnson was seeing home and business electrification

progressing in the United states and decided to branch out

to keep the company strong. Besides opening offices in other

countries to market lamps, he formed Aladdin Industries in

1919 to make products based upon vacuum technology. This was

followed with ventures into other household products. Lamps

were mostly a seasonal product and The mantle Lamp Company

needed products that would sell well year around keep the

income flow more steady.

Aladdin purchased a glass company in 1926 to gain complete

control over shade and chimney manufacture. This lead to the

introduction of glass lamps in 1932.

Aladdin was to keep its partnership with Plume & Atwood

for as long as metal lamps and burners were manufactured within

the United States. All American made metal lamps and burners

up through the Nashville model C were produced by P&A

for Aladdin.

Manufacturing Economics

Making tooling to form metal is expensive and takes time.

You need to sell a lot of lamps to pay for tooling

changes. It was a lot cheaper to have your company name stamped

onto existing generic parts than to pay for new tooling to

make different lamps. The fact that P&A was selling the same parts

to a number of companies just kept the prices more affordable

for struggling new marketing and sales companies and allowed

P&A to make a good profit.

When Aladdin first started working with Plume & Atwood,

they used P&As existing tooling to have their lamps manufactured.

As time progressed Aladdin's ability to pay for their own

tooling increased and the lamps became more uniquely Aladdin starting with the model 3 burner on generic P&A fonts.

But it was not until 1917 when the model 7 went into production

that Aladdin fonts became uniquely Aladdin. It is my guess

that the wild success of the model 6 lamp allowed Aladdin

to be able to afford their own unique tooling using features

that Aladdin quickly patented. Until the model 7 was introduced changes in fonts were replacement of worn out tooling or an improved method of joining the halves of the bowl at the chimes. Aladdin didn't just didn't go to P&A

and say make me an entirely new font tooling for the next

sales season that looks almost exactly the same as the previous year's font.

To keep costs down, tooling changes were minimal and the

existing tooling was used through as many models as possible.

If you compare individual stampings of adjacent models you

can get an idea of how many parts were carried over from

model to model and when tooling wore out and needed to be replaced during a year's production run.

Model 11 top with model 12 base, bottom and burner. Aladdin used up previous model parts transitioning to a new model

|

Unsold inventory is money already spent. It is not economical

to throw away parts that are already made if they can possibly

be made to fit in the next model. For example the

centre draft tube in my early model 2 table lamp has generator

seats for both model 1 and model 2 lamps. It appears to be

a reworked model one inner wick tube or perhaps a reworked

complete table font. The gallery on this model 2 lamp is a

model 1 gallery that was reworked to eliminate a top row

of holes. Model 3 gallery's are often found on early model

4 lamps. The first model 6 font lamps had the old style bottom

plates. Nickel plated model 7-8 gallery's have been found

on early model 9 lamps. There are several more examples of factory hybrid

lamps and burners that used up existing stocks. That's why I never argue

with an individual lamp that has a part or two from the previous

model. And I have seen way too many lamps with 12 burners

on 11 lamp bodies not to believe the factory used up extra

lamp bodies with an undocumented 11-12 transition lamp.

Many of these lamps can be explained by Aladdin's trade

in campaign allowing discounts for trading in earlier burners

for model 12 burners. But with the depression going

strong I do not think this program accounts for all the

lamps that have model 12 burners on model 11 lamp bases.

I keep wondering how many early transition lamps have been

modified by collectors who removed the "wrong" parts

and replaced them with the correct parts. I would imagine

that very few model 11-12 transition lamps survive a collector

in factory original condition.

When you look at the changes from model to model it helps

to keep in mind the economics of creating expensive tooling

and the need to get as much use out of it as possible. When

you look at individual lamps, remember the economics of existing

inventory at model change time. These two taken together can

give you a lot of insight to what you observe. |

Glass, Glass Glass!

In 1926 The Mantle Lamp Company purchased the Lippincott

Glass Company to produce glass lamps and shades. In 1930

the first vase lamps were introduced using model 12 oil

pots in Aladdin manufactured glass bottomless vases. These

same glass vases were also used to make Aladdin electric

lamps as well.

In 1932 the first Aladdin glass lamp was introduced with

the new model A side draft burner. Glass molds are much cheaper

to make than metal form tooling and Aladdin started producing

many styles each in several colours so that there was always

something new to entice the customer. The customer now could

choose among several styles and colours to match their room

decor.

The Old switcheroo

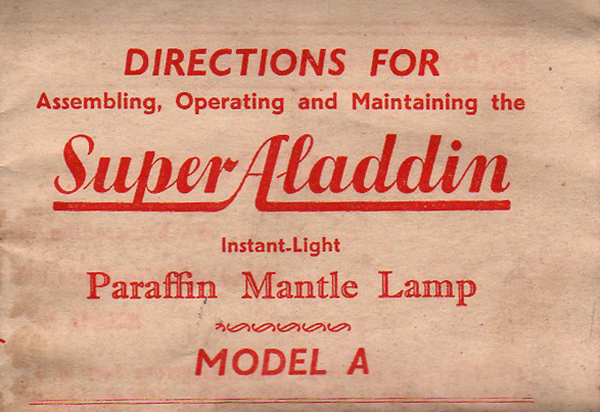

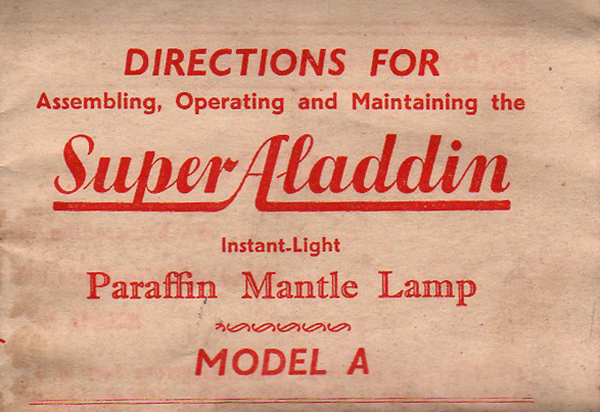

It appears that the Aladdin model A burner was originally intended to be sold in the United States and the model B was intended to be sold in the UK. The UK model B burner was introduced in the UK market in late 1931. The tooling for this burner was developed and located in the US.

A few months later the US model A burner was introduced in the North American market. The model A tooling was also developed and located in the US. Two sets of model A tooling were used during the year that the model A was in production for the North American market. This can readily be seen comparing model A burners made by the different tooling. It appears that US customers had problems with the difficulty of installing a new wick on the model A burners. The decision was made to keep the model B burner in the US to replace the US model A burner and to ship a set of model A tooling to the UK.

The British government had legislated stiff tariff taxes to products not made in the UK as a way to protect the British manufacturing industry. According to Bill Courter, The model A drawings, a set of tooling and presses were sent from Plume & Atwood to the Aladdin Greenford factory in time to start burner production before the new tariff came into effect.

During the time span between withdrawing the model B from the UK market and model 14 production starting in Greenfield UK, model 14 burners were manufactured in the US and shipped to the UK. Initially there were there were slight changes made to the tooling of both burners. Some of the model 14 differences between the burners imported from the US and those initially produced in Greenfield might have been differences between the initial 2 sets of tooling.

UK model B burner

|

Became |

US model B burner

|

US model A burner

|

Became |

UK model 14 "Super Aladdin" burner

|

Initially the UK Super Aladdin burner was called the Model A.

Soon thereafter the burner was referred to as the model 14.

We must all make sacrifices ...

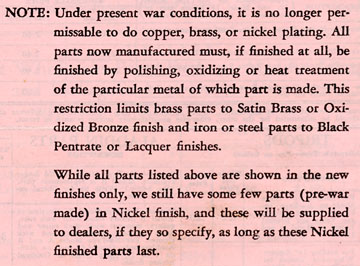

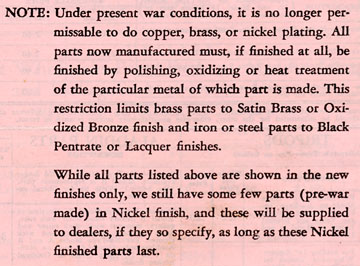

During world war II a number of materials needed for the

war effort became restricted. Brass was strictly rationed

during the war years as it was needed for shell casings and

many other uses. First to feel the restrictions was the Aladdin

UK division.

The Model 14 burner stayed in full production at Greenford

during WW II. Aladdin UK was granted a license by the Board

of Trade to buy rolled brass strip from certain ordnance factories

because lighting was considered essential.

In 1942 uranium became restricted in the United States and Aladdin had to change

their formula for Alacite. Brass had also become a restricted

product in the United States early in the war. Aladdin was

allowed to continue using brass for burners because much of

America was still unelectrified and the burners were designed

around the thermal characteristics of brass.

Production of brass metal lamps ceased until the war ended in 1945. Between

1942 and 1945 the only metal lamps manufactured by Aladdin

North America were steel font lamps for the caboose lamp market.

These font lamps were galvanized inside and out then coated

black. Wick cleaners, wick raisers, filler caps and threads made during these years

were also made from steel and then plated for resistance to

rust. At the end of the war, the steel font lamp was discontinued

and brass lamps went back into production.

From 1943 dealer price list.

Brass was also restricted during the Korean war and only glass lamps were available during that time. Aladdin Australia made lamp fonts out of steel during the war. Since

the outer finish of the WWII lamps was painted, these fonts

were not galvanized. Many of the fonts rusted from the

inside over time. There are Australian lamps that are part brass and part steel that were made during the transition as existing lamp part stock was used up.

Aladdin took their burner technology to the war effort with

a number of products ranging from field cook stoves and refrigerators

for field hospitals to shipboard coffee urns. In England Aladdin

burners were used in aircraft parked outside as dehumidifiers

to keep moisture out of equipment. The thermos products part

of the company branched out and grew as well.

The Mantle Lamp Company by any other name...

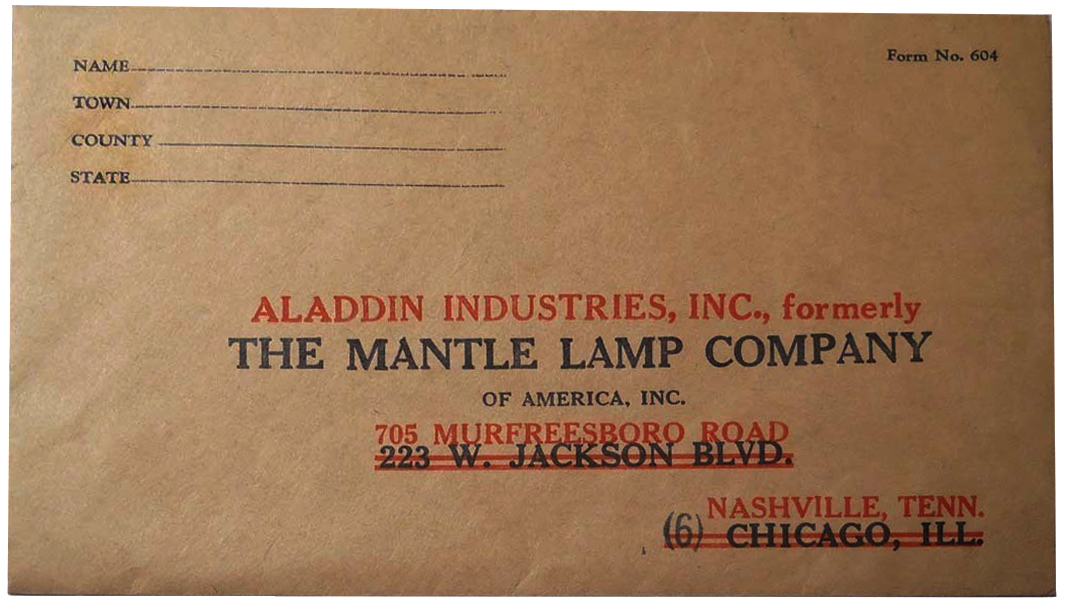

In 1919 The Mantle Lamp Company created a wholly owned subsidiary

named Aladdin industries to develop and sell thermos bottles

and other temperature conserving items. In 1949 the two companies

merged taking the subsidiary company name, Aladdin Industries.

Also in 1949 the Aladdin lamp line was revamped to minimize manufacturing costs with less expensive to manufacture lamp founts and accessories such as wall mounts and bug screens replacing more ornate (more expensive to manufacture) parts. Since post WWII housing construction had lower ceilings, ceiling extensions were discontinued. Less

expensive painted finishes were introduced to replace the more expensive plating finishes.

Interestingly, most American Aladdin Lamp collectors tend not to collect lamps or lamp accessories newer than around 1949. There seems to be little American collector interest in the Last of the model B lamps and the newer lamps that came afterwards.

Early regional sales office

Aladdin letterhead used during the 1940's until Aladdin moved in 1949.

All good things ...

By 1952 sales of kerosene lamps had decreased greatly with

the post war electrification of rural America. The glass

plant was closed and almost all the lamp molds were destroyed.

The mold for the plain stem Washington drape (B-53) and

the glass font lamp were retained and an outside company

produced lamps from these molds until model B was discontinued.

Aladdin headquarters was moved from Chicago to Nashville

in 1949. At this time the wick adjuster knob tooling was changed

so that Chicago was replaced by Nashville on the model 12

and B burners (12 burners were still in production for the

parts replacement market and possibly export).

A flood in August 1955 severely damaged the Plume and Atwood Waterbury Connecticut manufacturing plant. The flood washed away or destroyed the tooling used to make Aladdin lamps and burners. This abruptly ended model B production

and the production of new replacement parts for older lamps. Until

then model 12 burners, model 6 and 12 flame spreaders and

model 6 wick carriers were still in production to help existing

customers keep their model 3 through 12 lamps working properly.

By this time Aladdin's lamp business generated only a very

small percentage of the company profit and Aladdin

did not want to put any real money into new high quality

tooling that might not get a return from lamp sales. The

remaining stock of model B burners were allocated to B-53

lamp production and when the surviving stock of burners ran out the model B was discontinued. This lamp with

a Nashville burner was the very last of the Aladdin model

B lamps, and the last Aladdin glass lamp for a few decades.

When the flood damage was cleaned up, a model

C burner was tooled up by Plume & Atwood (small round

wick adjuster labeled Nashville) and lamps were made using

inexpensive aluminum materials for the fonts. The aluminum lamps looked

cheap and I suspect sales reflected the looks. The newly hastily designed model C burner never worked very well. Meanwhile Aladdin England had a new model 21 burner that worked well. I often wondered why Aladdin Nashville didn't just start importing the model 21 burner. Eventually the model C burners were discontinued and replaced by the UK made model 21 burners, labeled 21C.

England had its own burner tooling and was not affected

by the flood in America, but economic pressures led them to revise

the model 14 burner to make it less expensive to manufacture. Improvements

were added at the same time and the model 21 was born in

1953

The Australians never made their own burners. They

were importing UK model 14 burners and offering them as model

16A burners. They were also importing American model

B lamps an offering them as model 16B. After 1954 Aladdin

Australia sold lamps with UK made model 21 burners.

In 1963 Aladdin UK model 21C burners were imported to the

US to provide a higher quality alternative to the model C

aluminum lamps.

The model 23 burner (reworked model 21C burner ) was introduced

in 1969. The first model 23 burners were English made. Eventually

model 23 burner production was moved to Hong Kong (The English

tooling stayed in England and new tooling was made in Hong

Kong). There were a number of fit and quality issues with

the Hong Kong burners that slowly got worked out over time

and through several versions of the burner.

Inexpensive model C lamps were made in Brazil in 1974-75

primarily for the third world export market and as a low cost

alternative to the expensive model 23 lamp in the US market.

However the steel Brazilian burners did not work well at all.

Sometime during 1975 new Brazilian burners were shipped to

Aladdin UK for modification to correct burning problems. The

root problem is that the Aladdin burner technology evolved

using brass thermal characteristics and the Brazilian burners

were mild steel. It was concluded that the design could not

work properly with the different thermal characteristics of

steel and the Brazilian model C burner was discontinued.

By the late 1980's the Chinese company producing Lox-on chimneys

for Aladdin was having problems producing the chimney foot

and chimneys were being sold that required reworking of the

gallery tabs and sometimes even then did not stand straight

on the lamp.

Through much of the 1970s, '80s and going into the '90s

Aladdin had been outsourcing to low cost manufacturers who

just were not making parts that fit or worked well. Expensive

lamps were being offered for sale that often did not fit or

work quite right. It seemed that Aladdin Industries just did

not want to discontinue its root business nor did it want

to spend the money and effort to revitalize it. The Aladdin

lamp division seemed to be sliding slowly towards oblivion

as the lamps slowly faded from public memory. By 1998, Aladdin's

lamp division profits were around 1% of the Aladdin Industries

annual income.

But wait!

On 5 April 1999 a group of Aladdin enthusiasts headed by

J. W. Courter and Tom Teeter purchased the Aladdin mantle

lamp division from Aladdin Industries. Tom Teeter owned a

company named The American Lamp Supply Company that offered

reproduction and new classic lamps that used the model 23

burner. The merging of the the two companies provided a large

increase in Aladdin lamp models. The new company was named The Aladdin Mantle Lamp Company.

The new company focused on upgrading the quality

of that lamp parts and providing the product line with a

much needed face lift that better reflected the Aladdin lamp roots. At this point it seems that the new company is largely supported

by sales of limited edition boutique lamps to collectors.

By 2014 some of the partners running the Aladdin mantle lamp company were ready to retire and the company was sold to Lehmans at the end of 2014 and beginning of 2015. The Aladdin Mantle Lamp Company became part of the Crownplace Brands division of Lehmans.

In early 2015 the company assets were transfered from Tennessee to Dalton Ohio.

The unsung Savior of Aladdin

I believe that Aladdin today owes its very continued existence

to Aladdin Industries Ltd, UK. The British empire imposed

strict import tariffs early during the great depression to

protect British industry and provide workers with jobs. The

Greenford manufacturing plant was built to make Aladdin kerosene

heaters, lamps and other products for sale within their empire.

The Greenford plant opened in 1932. Before then all Aladdin

lamps sold into the empire were of American manufacture, even

if the wick adjuster knob said London.

As an aside, Chimneys made for Aladdin UK were manufactured by the glass-makers Chance Bros in England, a very large concern that was in business from 1824-1981 and employing over 3,000 people at its height. Records indicate that in 1934, Chance was supplying Aladdin UK with 12,000 chimneys per week. The 'Hysil' trade name often associated with these chimneys derives from Chance - a borosilicate (heat-resisting) glass mixture. The trade name was bought by J A Joblings (the UK licensee of Pyrex) in about 1960.

I do not know for sure who manufactured glass shades for Aladdin UK, but it was highly likely that this was done by Chance Bros. as well. They had a large department for manufacturing opal-flashed glass. So they had the means to make the shades for Aladdin UK. (This data is from research done on the Chance Bros. by David Encill).

Americans did not accept the difficulties involved with

inserting a wick into the model A burner. With the wick

adjustment gear inside the wick movement area the wick tended

to hang up during insertion. The model A burner tooling was shipped to the

Greenford plant in the UK and the model B tooling stayed in the Connecticut Plume and Atwood manufacturing plant.

The slightly modified model A tooling became the UK model 14 (Super Aladdin) burner

that was used through 1953. This burner was also sold into

Australia as the model 16A.

In 1954 this tooling was modified to incorporate improvements

and reduce manufacturing costs. This reworked burner

become the model 21, then later the model 21C. The superior burning and quality English model 21C lamps

replaced the P&A made model C lamp in 1963. In 1969 the English tooling was revised yet again and became the

model 23.

Had it not been for Aladdin Industries UK, Aladdin lamps

could have very likely gone out of production sometime between

the mid nineteen sixties and seventies. Every Aladdin burner made today is a direct descendant from

the model A tooling sent to the UK and the common model 23

brass table font is a direct descendant from the UK model

12 table lamp.

If it was not for the transfer of the model A tooling to

Greenford UK, the 1955 flood that swept through the

P&A factory would have spelled the eventual doom of Aladdin

Lamps.

* From Aladdin The Magic Name in Lamps revised ed. page 43 "The Mantle lamp Company purchased and assembled lamps and accessories they sold from 1908 until late 1910 or 1911. These included the Practicus, No 1 Sunbeam and models 1 & 2." and page 44 "Johnson applied for trademark registration of the name Aladdin while he continued selling the Practicus, soon replacing it with the Sunbeam burner made by P&A. At the same time he was in the process of negotiating with P&A for a center draft mantle lamp that he would name Aladdin." Quoted with permission from the author, Bill Courter |

TIME LINE

1908 Mantle Lamp Co. Founded. Sold Practicus lamps

1908, possibly early 1909 mantle Lamp company no longer selling Practicus lamps and started selling Sunbeam mantle lamps.

1909 Aladdin Model 1lamp introduced, complete Sunbeam lamps no longer being sold.

1910 first two Canadian offices opened

1911 First patent covers new mantle, gallery &

generator. Cap mantle replaced by KoneKap mantle

1913 First wick cleaners, with model 4

1915 Model 6 First floor lamp

1915 Model 6 floor lamps converted to electricity

became Aladdin's first electric lamp.

1915 Model 6 won gold metal at World's Fair

1917 US entered WWI and parts for competitors

using German made burners, mantles & chimneys became unavailable

putting them out of business. Aladdin chimney production moved from Germany to US.

1917 Model 7 was first lamp using all new tooling

designed just for Aladdin

1917 First bug screens

1917-18 saw a slew of patents making the Aladdin lamp

unique from the competition

1918 Aladdin granted patent for #6 burner possibly

spelling end of production for other companies using P&A

designed mantle lamps.

1919 Aladdin Industries Ltd. UK

1919 Aladdin Industries founded to make vacuum bottle

products

1921 Model 10 first reinforced wicks & end to

wick carrier

1924 Aladdin Industries Ltd Australia

1926 Lippincott Glass Company purchased

1928 First Aladdin manufactured glass shades

1928 First paper shades

1928 Name generator changed to flame spreader

1928 Model 12 Lox-on mantle and chimney introduced

1930 Production began on electric lamps

1930-1935 Model 12 vase lamps

1932 First glass lamps

1932 Australian manufacture of lamp bodies started.

Never manufactured burners

1933 First English made lamps

1935-1954 Glass font lamps

1937 First caboose lamps

1938 First Alacite lamps

1938 Aladdin glass shades discontinued thru 1951

1942 Alacite formula changed

1943 Name bug screen changed to insect screen

1943 -1945 No brass lamps manufactured

1944 - 1952 bakelite lamps were manufactured

in Australia

1949 Mantle Lamp Co. merged with Aladdin Industries

1949 Main offices moved from Chicago to Nashville,

Model 12 & Model B Nashville burners thru 1954

1949 Much of the lamp line revised.

Paint replaced plating for most metal lamp applications.

1951 Outsourced glass shades available

1952 Glass plant closed All glass molds destroyed

with exception of plain stem Washington drape and font.

1952 Last floor lamp

1955 Flood destroyed all metal lamp and burner

tooling. Model B discontinued. Remaining burner stock on

hand went to B-53

1955 Last Aladdin glass lamp, B-53, removed from price

list

1974 Glass lamp production resumed with undated model

23 Lincoln Drape

1978 Aladdin manufactured a small number of model 23 student lamps for its 75th anniversary. They were priced high and not readily available to the average consumer. Eventually the last stock was sold cheaply through an inventory liquidation house. These have become valued by collectors.

1984 Aladdin Canada closed

1994 Fenton started manufacturing a line of glass

lamps for Aladdin

1999 Kerosene lamp division sold. New owners put a lot of effort into manufacturing quality and expanding the product line.

2008 Aladdin reintroduced the parlor lamp fount design was a model 23 lamp as a 100th anniversary commemoration lamp.

Late 2014 The Aladdin Mantle Lamp Company was sold to Crownplace Brands the wholesale and manufacturing division of Lehmans.

2015 Aladdin moved from Tennessee to Ohio

2015 MAXBRITE 500 burner introduced.

|

![]()

![]() Contents > Brief

history of Aladdin lamps

Contents > Brief

history of Aladdin lamps

And sometimes the advertisement reminds you of Aladdin brand lamps every time you hand sew.

And sometimes the advertisement reminds you of Aladdin brand lamps every time you hand sew.